Geothermal power businessInquiry

- Two PIP melting methods

-

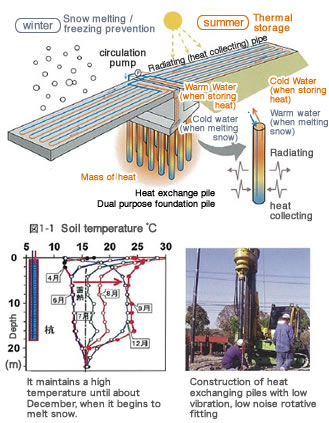

The PIP snow melting method, a new system that enhances heat efficiency by enabling energy saving, low cost snow melting, which enables seasonal thermal storage, has been added.

・Solar / pile system (group pile / summer preservation system)

What is geothermal energy...?

- ・ Relatively low temperature thermal energy in the ground of about 5 m to 200 m from the ground surface.

- ・ It is almost constant temperature throughout the year without being influenced by temperature fluctuations.

Approximately the same temperature as the annual average temperature of the area (e.g.,: Tokyo around 17 ℃, Sapporo around 10 ℃, Fukui around 15 ℃)

Methods of using geothermal energy

-

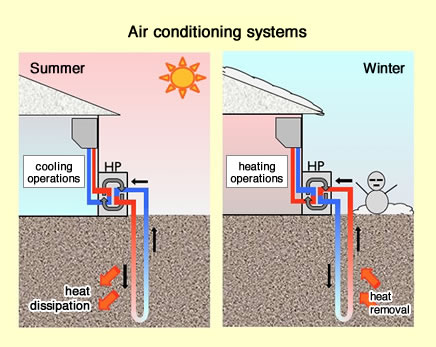

- ・In the summer, heat is dissipated into the ground, and in the winter, heat is taken from the ground.

- ・ It is effective for suppressing greenhouse gas generation in summer.

-

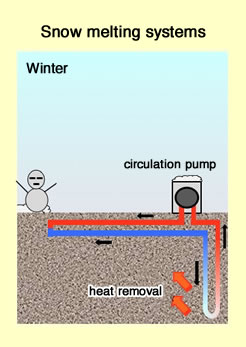

- ・It melts snow using heat from the ground.

- ・It also enables the accumulation of solar heat in the summer.

Mitani Sekisan’s Approach to the Use of Geothermal Energy

-

- 1. Heat exchangers utilizing foundation piles (install underground heat piping in the hollow of piles of foundation piles)

- 2. Heat exchanger with underground heat exclusive pile (can be installed at the position without foundation pile.)

Solar / pile system(group pile / summer preservation system)

Melting the snow by storing the heat from summer in the ground!

If only you could keep summer heat until winter... a new technology has been created to make such a dream possible! The group pile makes heat mass and stores the heat of the sun in the ground, so it can be used for energy saving and cost saving as well as measures against heat islands as well.

In the case of using only geothermal heat as a heat source, it was necessary to separate the spaces of heat exchanger piles to such a degree as not to mutually interfere. In the case of underground heat storage, spreading of heat is suppressed by installing it densely closely (group pile method). In addition, by making a mass of heat in the ground, it is possible to store it for more than half a year. In the solar pile method, the number of piles can be reduced to less than half compared with the conventional method using only geothermal energy as a heat source. In addition, installation of a heat exchange pile can be done easily and cheaply by utilizing the foundation pile construction method widely used at construction sites and so forth.

People-friendly, environment-friendly, clean snow melting using solar and geothermal heat

- Do not use an artificial heat source or ground water

-

Because the heat source for melting snow is geothermal and solar heat, an artificial heat source is not necessary. Also, groundwater is clearly unnecessary because of the circulation system. Furthermore, with a solar pile system, it is possible to melt snow in Hokkaido using only natural heat sources.

- Costs for construction and maintenance are inexpensive (power consuption is a tenth to a twentieth of electric heating)

-

The heat source portion can be constructed at a low cost by using foundation pile structures. Even in the case of construction with a dedicated heat storage pile, the solar pile system saves on costs as it can reduce the number of piles needed due to high heat storage rate. The maintenance cost consists only of the cost of electricity for the circulating pump operation, so it is very inexpensive.

- Easy to walk due to not spray water, also serves as a measure against heat island

-

The system is a system that makes it easy for people and pets to walk because it does not spray water during the process of melting the snow, and it cools the road surface near 70℃ in the summer by circulating cold water.

- On top of pavement thickness being reduced, heat conduction is also increased

-

We were able to reduce the burial depth of the heat sink tube to 4 cm by mixing steel fibers and expanding agents in the concrete pavement (fiber concrete). Because of this, the thermal conductivity is greatly improved, and as the aggregate of the concrete is silica, the high thermal conductivity is as always.

- Wet on wet, cost saving

-

We constructed ordinary concrete beneath the heat sink tube and use a wet on wet construction method to quickly force fiber concrete after setting so that only a necessary amount of expensive fiber concrete was used. This method resulted in cost savings.

- Workability UP, costs DOWN by reducing bending of piping

-

By distributing the dry shrinkage of concrete with continuous reinforcing bars and radiating tubes, we are improving workability with the minimum necessary for the objective (i.e., straight-line type), resulting in cost savings.

- Complex technology to accommodate various facilities, from planning to completion

-

From the proper facility plan using simulation software, heat source technology such as group pile and foundation pile utilization technology, heat dissipation technology such as wet on wet ・ straight type ・ pigment mixing, further control can be appropriately handled to various facilities from low cost to high precision.

- PIP air conditioning

- Heat exchange piles can be used for air conditioning equipment throughout the year. In particular, with the solar pile system, the operation efficiency of the water heat source heat pump is greatly enhanced by the effect of seasonal heat storage, and the annual energy saving amount compared with the air heat source heat pump has been confirmed to be over 20% in terms of electricity consumption.